Improperly maintained equipment invariably leads to unscheduled shut downs and increases the chances of injury to passengers. The life expectancy of the equipment is also substantially reduced.

Improperly maintained equipment invariably leads to unscheduled shut downs and increases the chances of injury to passengers. The life expectancy of the equipment is also substantially reduced.

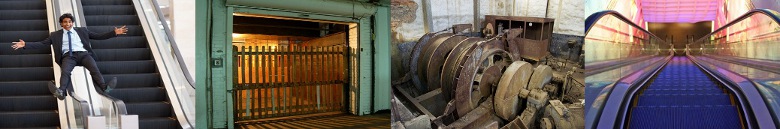

Transferring anything on an escalator is inherently dangerous. It has often occurred that the articles being transferred have jammed an escalator causing it to stop quickly causing others on the stair to fall, with severe injuries resulting. In addition baggage on the escalator has jammed causing other passengers to fall over it.

Transferring anything on an escalator is inherently dangerous. It has often occurred that the articles being transferred have jammed an escalator causing it to stop quickly causing others on the stair to fall, with severe injuries resulting. In addition baggage on the escalator has jammed causing other passengers to fall over it.

What the riding public should never see! The two circular metal mechanisms in the foreground are the door operator sheaves which open and close the car doors. They are controlled by the blue box immediately above and behind the sheave assemblies. To the left of the blue box is the door operator motor. The railing around the outer perimeter of the car top is a safety railing to prevent accidental falls. The blue rail running perpendicular to the safety railing is the cross-head, which is a part of the sling assembly, within which the cab is installed. Mounted on the cross head, from left to right, is a car-top inspection run box, the hoist cables, and a light assembly.

An example of a very typical overhead traction-type (cable type) driving machine. Machine components, as viewed from left to right, are; the DC current hoist motor, the brake assembly, and the large round traction sheave. The hoist cables (ropes) can be seen projecting from the front and rear portions of the traction sheave. One side of the hoist cable(s) descends down the hoistway and secures to the elevator car top. The other side of the hoist cable(s) descends and connects to the counterweight assembly.